Select language

Milling

We use both 3-axis and 5-axis milling machines to achieve high precision in complex tasks. Our experts program Hermle and DMG machines with Hypermill, and digital workflows ensure efficient preparation and production. Automation and robotic loading allow us to operate unmanned for cost-effective manufacturing.

Capabilities:

- Max size: 500 x 500 x 500 mm

- Batch size: Single units up to ~500 pieces

- Materials e.g.: Steel, aluminum, stainless steel, titanium

Cleanroom

VDL MPC has over 300 m² of cleanroom space, classified as ISO 7. In this cleanroom, we assemble and/or clean products in a highly controlled environment. The cleanroom is fully equipped for qualification and testing. It includes a separate area for plasma cleaning, an ultrasonic cleaning line, and a special blacklight inspection room.

To prevent contamination, all parts and modules are cleaned, assembled, and packed in this controlled environment. Our ISO Class 7 cleanroom meets the highest industry standards, including those of the semiconductor industry. With years of experience, our specialists ensure top-level precision and quality in the cleaning and production of your components.

Bending

To create bends in products, we use press brakes, also known as bending, folding, or pleating machines. During this process, a flat sheet is pressed by an upper punch with great force into a lower die, resulting in a bent angle with a bending radius.

Thanks to our advanced CNC machines from LVD and Safan Darley, we can bend virtually all metals (stainless steel, steel, aluminum) up to a length of 3 meters. The sheet blanks are precisely cut in our laser cutting department, ensuring a perfect fit and finish.

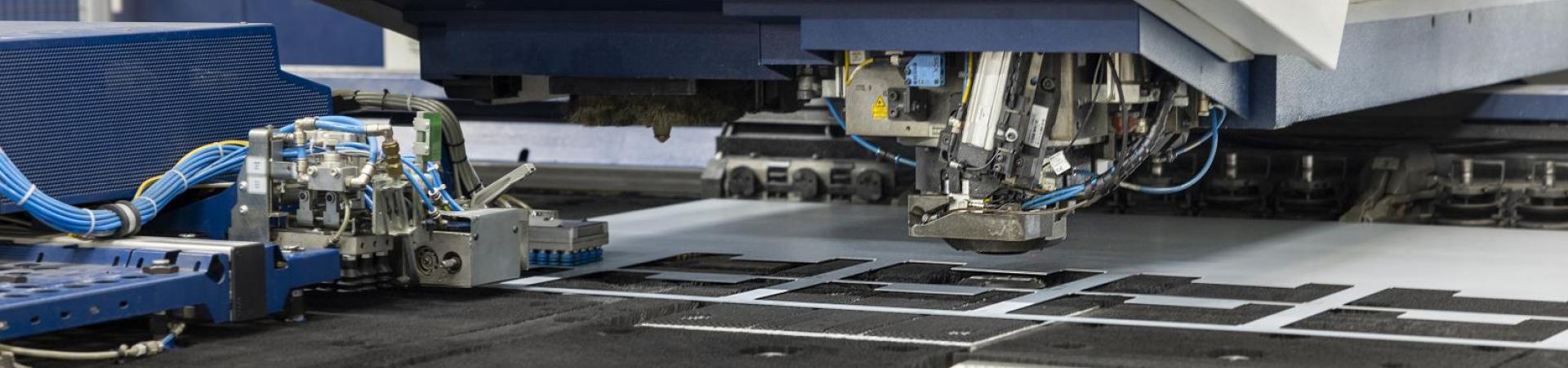

Laser cutting

Laser cutting is a precise method of metalworking. The laser cuts the desired shape from the metal sheet, which is then processed into the final product.

At VDL MPC, we use machines such as the Trumpf TruMatic 7000 with loader for unmanned hours and the Mitsubishi ML3015eX-60XF. These machines enable us to work with high precision and efficiency. After cutting, the products are neatly finished by our Timesaver for deburring, edge rounding, finishing, and/or removal of laser oxide.

Caapabilities:

- Max size: 3050 x 1550 mm

- Thickness: Up to 30 mm for steel

- Batch size: Single units up to ~500 pieces

- Materials e.g.: Steel, aluminum, stainless steel, titanium

Manual Welding

Our welding specialists have years of experience and provide you with the right solution for your application. Whether it’s large or small welding assemblies, VDL MPC is your reliable partner. We have an extensive welding department where various welding techniques are applied, including:

- MIG/MAG welding

- TIG welding

- Spot welding

- Sheet metal welding

- Stud welding

Robotic welding

At MPC, we use a Yaskawa robotic welding machine. This robot offers precision and efficiency, allowing us to perform complex welding tasks at high speed and consistency. Thanks to this robot, we can guarantee high-quality welds.

Construction mechanics / Metalwork

The craft of metalwork requires precision, skill, and craftsmanship. Our professionals repair and process products using multiple machines to ensuring utmost accuracy. Additionally, assembly plays a crucial role in our work process. By carefully assembling various parts, we create high-quality end products that meet the highest quality standards. Both metalwork and assembly require a keen eye for detail and a thorough knowledge of materials and techniques.